Translate:

Innovative Solutions featuring premium performance in filtration and silt separation!

EN

Translate:

Innovative Solutions featuring premium performance in filtration and silt separation!

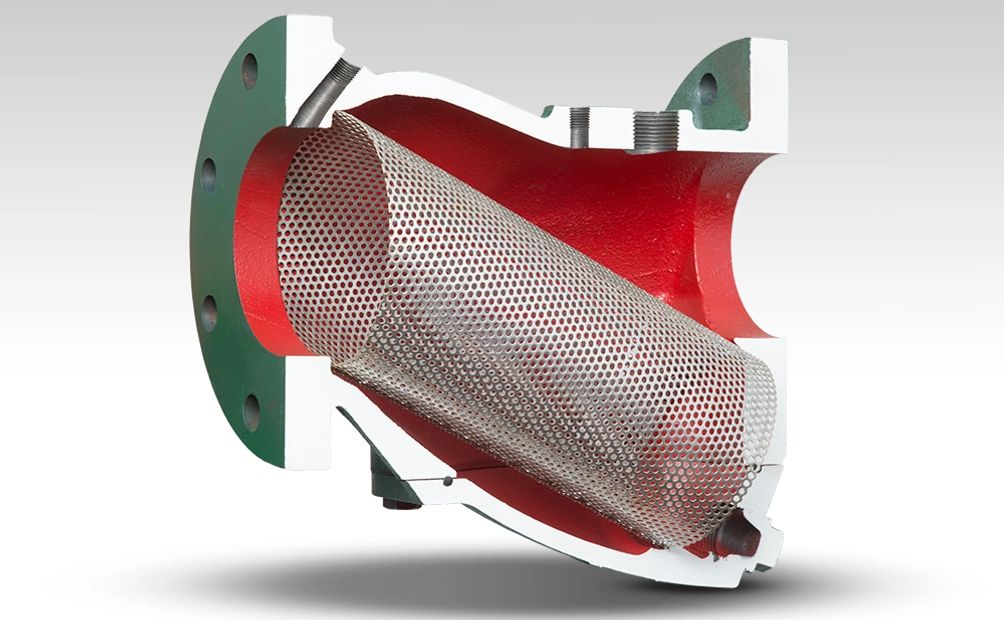

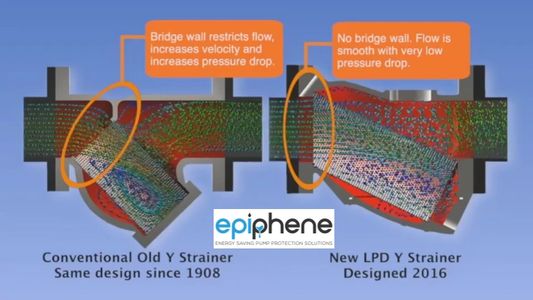

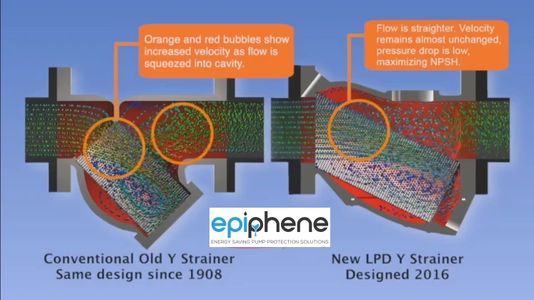

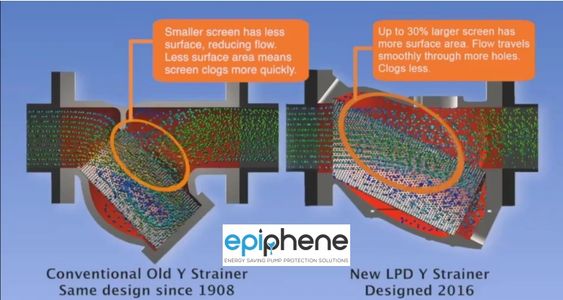

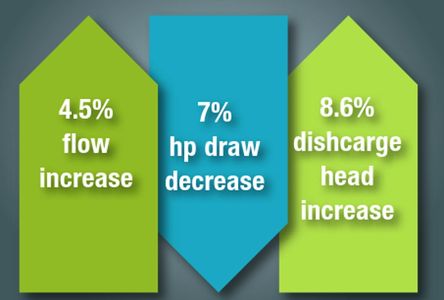

Low Pressure Differential Strainers offer a huge positive impact on energy savings, pump discharge head, and increasing flow rate. Positive impact on designs in motor, pump and strainer sizing.

Useful in protecting against turbulence upstream of pump suction, flow meters, and valves installed after elbows. Also reduces pressure losses on pump suction resulting in positive impact on motor and pump selection as well as reduces overall energy use.

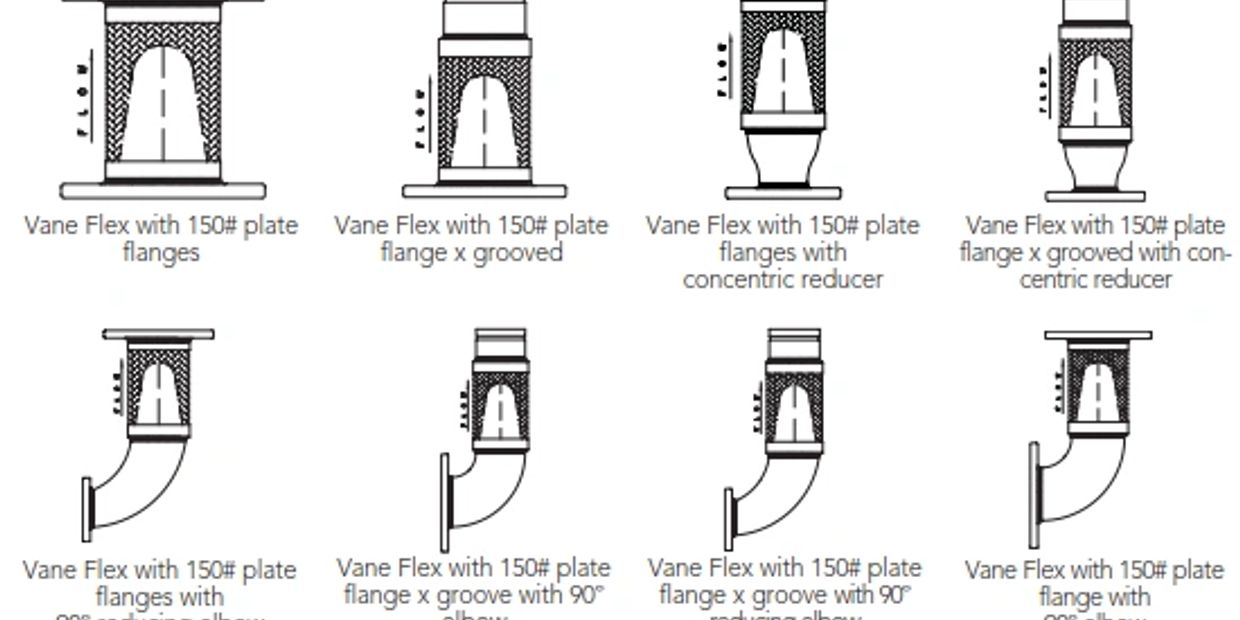

This device does dual duty as both flexible coupler and turbulence mitigation before flow meters, valves and other applications that need it.

22.5 degree alignment of Screen allows for less space underneath the strainer.

Strainer calculator offers valuable tool to evaluate the use of this energy savings solution as compared to traditional strainers.

Flow Rate Improvements for LPD "Y" strainers against typical "Y" Strainer offerings average 59% across sizes offered.

Innovative Design reduces pressure losses significantly and less space using shallower angle for screen and studs in the down stream flange,

Straight through flow design reduces turbulence and head loss affecting pump suction.

Larger Screen means less clogs and operates far better in difficult applications.

Combining these two solutions can address tight spaces often encountered in buildings and other applications.

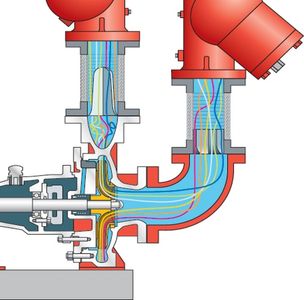

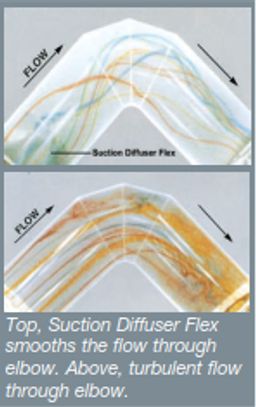

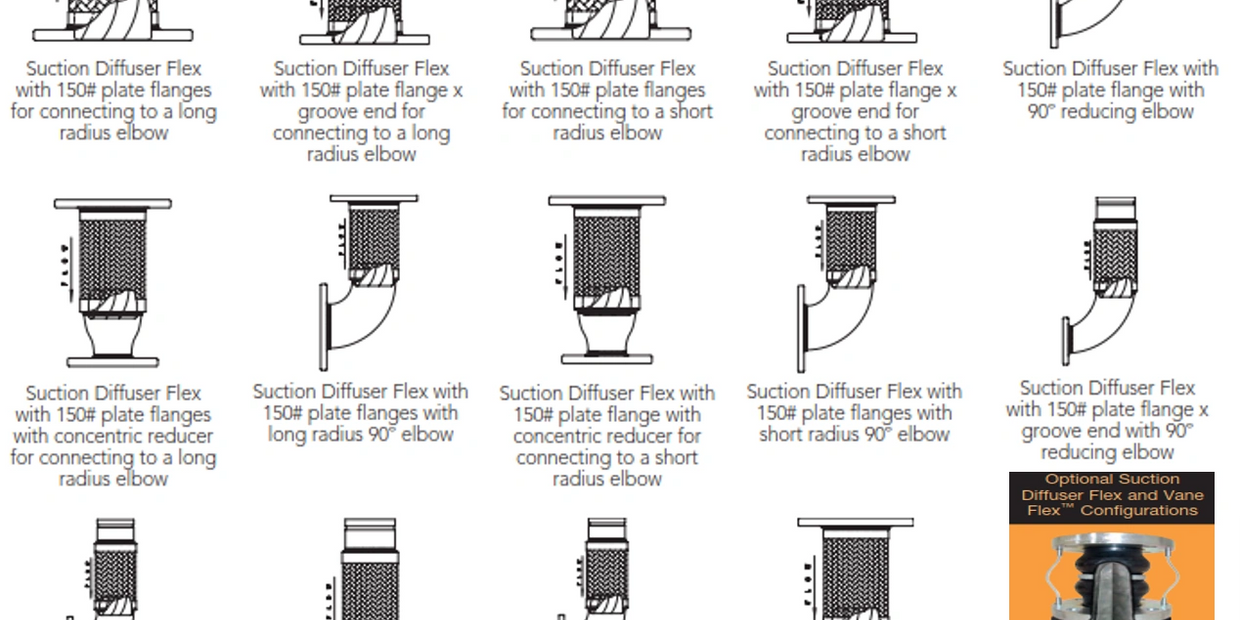

Often we encounter design requirements that call for elbow into a pump...this creates many issues for a pump including potential cavitation and reduced performance due to increased head losses on suction side.

As seen in the chart below there are many additional issues addressed by removing turbulence and non-uniform flows associated wtih elbows.

As seen in the chart above there are many additional issues addressed by removing turbulence and non-uniform flows associated wtih elbows.

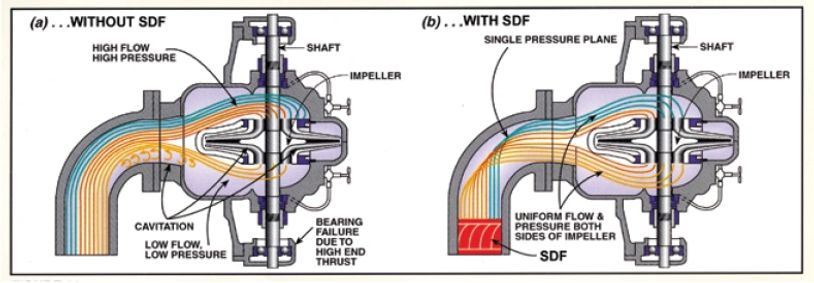

(a) Shows low flow and low pressure leading to cavitation and pump damage.

(b) Shows SDF installed and evenness of flow and pressure on pump suction.

Custom installation of SDF on Elbow prior to pump resulted in triplihg life of pump to 18 months,

The main problem was removing the causation of cavitation but we also recorded significant improvements in pump performance.

Versions include tapered and most major connection configurations such as flanged and grooved.

Flexible pump or pipe connector conditions flow providing 10 pipe diameter turbulence reduction with specially designed hydrodynamic shaped vanes.

Reduces discharge turbulence in a fraction of the space - typically

Protects valves including check, control and balancing downstream form flutter and damage allowing for longer life and better performance.

Works as Flow Conditioner and Flexible Connector to isolate piping from pump.

CFD Graphic above shows actual test result where turbulent flow transitioned to laminar flow due to Vane Flex.

If you need something specific not pictured, here let us know your requirement.

Please call or contact us via email and we will endeavor to get back within one business day or sooner.

Monday - Friday: 9am - 5pm

Saturday: By appointment

Sunday: Closed

This website uses cookies. By continuing to use this site, you accept our use of cookies.